Providing cost effective options for compost production

The system has been designed as a cost-effective solution to address the challenges associated with traditional composting methods, while minimising both capital and operational expenses.

Our unique technology

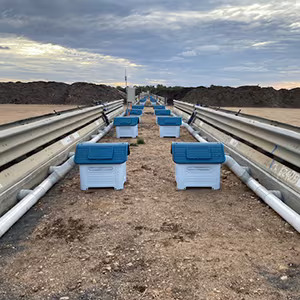

HEAPS – Autonomous Composting System

Efficient

Optimises the conditions for composting by constantly monitoring the material and applying air and moisture as required.

Effective

Optimum conditions make the process fast and reliable. Similar inputs will produce similar outputs in consistent process times every time.

Low production costs

Low capital costs

HEAPS systems are simple and generally represent lower capital investment than turned windrow systems and are a fraction of the investment required for ‘in-vessel’ systems while delivering comparable outcomes.

Scalable

Flexible

Systems can be designed to meet site parameters and can be retrofitted to existing facilities. In most cases HEAPS systems require <20% of the land space required for turned windrow systems with similar throughput. Containerised systems are available for deployment to short term tasks and in response to natural disasters.

Adaptable

HEAPS can be designed from a simple redeploy-able system to fully functional in-vessel systems to meet your needs.

Compliant

The HEAPS controller records composting conditions every 20 minutes. The data is stored in the cloud and can be matched with weather station data to meet regulatory compliance requirements.

Operators can upload input data to maintain a contemporary record of material inputs and outputs.

Communication

Autonomous

Once the HEAPS is loaded, the system will optimise the process until complete. No further human or mechanical input is required. Operators can interrogate the system via the app 24/7 but are not required to take any action unless they wish to do so until the process is complete and the HEAPS is emptied.

Supported

Radicle Agriculture offers training, monitoring, and warranty support including provision of regular system performance reports and finished produce analysis and recommendations.

We have been there, seen it and done it before and are ready to help you.

Recyclable

All HEAPS components can be recycled and recycled materials are utilised in system design where possible.

Our HEAPS system composts FOGO with minimal labor and no odor, we are very satisfied with its performance and efficiency

Christine Blanchard,

Regional Queensland Council Waste Manager

FAQ

When you follow the basic rules the composting process does not produce unpleasant odours. If any of the critical elements of carbo to nitrogen ratio, moisture levels and especially oxygen saturation are outside of some basic parameters, then volatile gasses may be released and aerobic conditions may result. Anaerobic conditions are the primary cause for the creation of objectionable odours. Fortunately, FOGO generally presents with suitable carbon the nitrogen ratios and the HEAP’s controls the rest.

The system constantly monitors oxygen availability in the HEAPS. The system then uses blowers to introduce air into the HEAPS when it falls below pre-set parameters and stops once optimum pre-set levels are achieved. It is interesting to note that the system generally introduces air for around 10 minutes every 1 – 2 hours to maintain optimum oxygen saturation. This level of efficiency is not possible with turned windrows inevitably resulting in the development of anaerobic conditions.

Absolutely, one of the exciting features of the HEAPS is its adaptability and scalability. Whatever the volume and rate of production of your organic waste stream, we can design a HEAPS to meet your needs. This offers the opportunity to establish a HEAPS at each collection point rather than a need to transport material to a central location for processing with considerable lifetime cost savings.

Electrical power is required to operate the water pumps and air blowers intermittently. The control system including the sensors require limited power constantly. The system is ideally suited to operating with solar power supported by battery storage of as a hybrid system using solar, and mains/generator power supply.

Maintaining an optimal moisture content in the organic material is critical to efficient composting. At the desirable moisture content no leaching occurs. The HEAPS maintains moisture content this autonomously. Preventing excess moisture resulting from rainfall can be achieved with simple covers, which can be left in place throughout the process, or a roof. Fully enclosed vessels are not required.

Inevitably composting time depends on the input materials. A planning figure of between 9 and 12 weeks should be used. Systems cab be designed to operate on input batches or on regular daily/weekly/monthly input flows. Depending on the material, a further maturation period in a static pile may be recommended.

There are three types of contamination. The heat generated by the thermophilic phase of the composting process (>65ºC for over 8 weeks) destroys biological pathogens. Chemical contamination can be avoided by careful selection of the input material which leaves physical contamination. While the HEAPS does not remove physical contamination the lack of mechanical action in the process means that plastic bags, glass , cans and other containers remain intact, making it much easier to mechanically screen these out at the end of the process.

Mechanical turning of organic material is employed to assist with three key elements of the process, aeration which is optimised at the time of turning but rapidly dissipates until the next turning event, mixing to ensure all the material is exposed to heat and physically reducing particle size. The HEAPS are designed to ensure effective heating throughout the organic material. The system benefits from having particles of various sizes as this assists with air flow throughout the HEAPS. Oversize material can be reintroduced to subsequent batches or ground either before or after the process. Importantly, the lack of mechanical turning ensures that physical contaminants remain intact for easier extraction post composting.

Significantly less than the area required to windrow compost a similar volume of material. The HEAPS can be called to meet throughput requirements and adapted to meet site parameters.

Simply build the HEAPS and leave it for the automation to control the process and advise you when its ready to be screened. That’s it. No ‘in process’ labour required, none.

The HEAPS can be used to compost any suitable material. Once the appropriate inputs are identified and the HEAPS constructed, the system takes care of the rest as efficiently and cost effectively as possible.

As with any composting system the smaller the particle size the greater the surface area for the microbes to operate and the more efficient the process. However, it is also important that the material is not too dense in order that air and moisture flows and be maintained. The system works effectively on FOGO (curbside collection), cotton trash and manures without the need for pre-processing.

HEAPS of progress with FOGO

Discover how HEAPS has assisted with FOGO in the Lockyer Valley Regional Council.

Get in touch with us today to explore how we can assist you in capitalising on the advantages of the HEAPS composting system and transforming your organic waste into a valuable resource.